Typical Spray Coats

- Ni-/Co alloys / stainless (Stellite, Triballoy, Inconel)

- Carbides/cermets (tungsten carbide, chromium carbide)

- Material form: powder

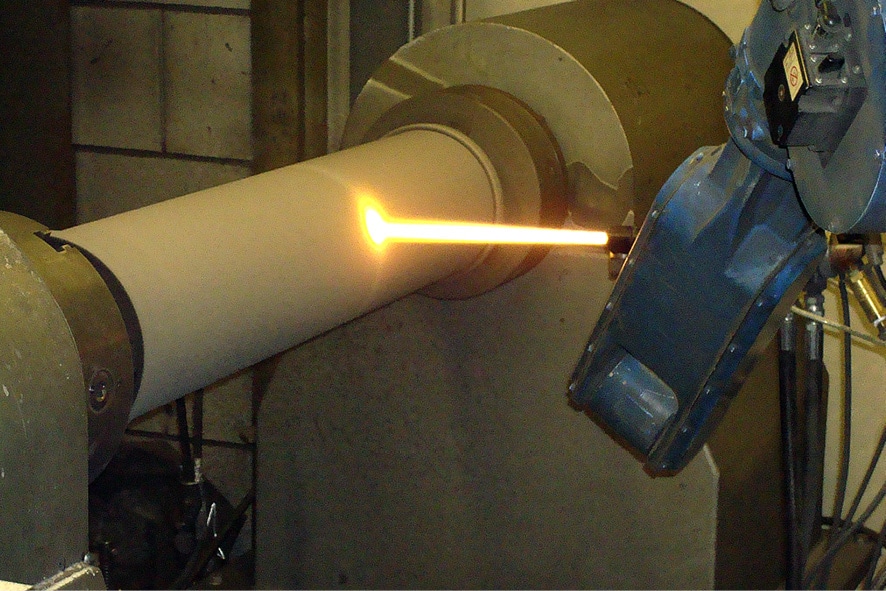

- Combustion of kerosene with oxygen

- Flame temperature: 1,500-2,500 °C

- Particle speed: 400-800 m/s

COLLEGA GEZOCHT

Conventioneelverspanner / Slijper gezocht!!

Loop binnen of maak een afspraak.