Typical Spray Coats

- Self-flowing alloys (fusing)

- Ni/Fe/Mo base materials

- Ceramics/cermets

- Wear-resistant layers (Ni-graphite)

- Plastics (e.g. Rilsan, polyamide)

- Material form: powder

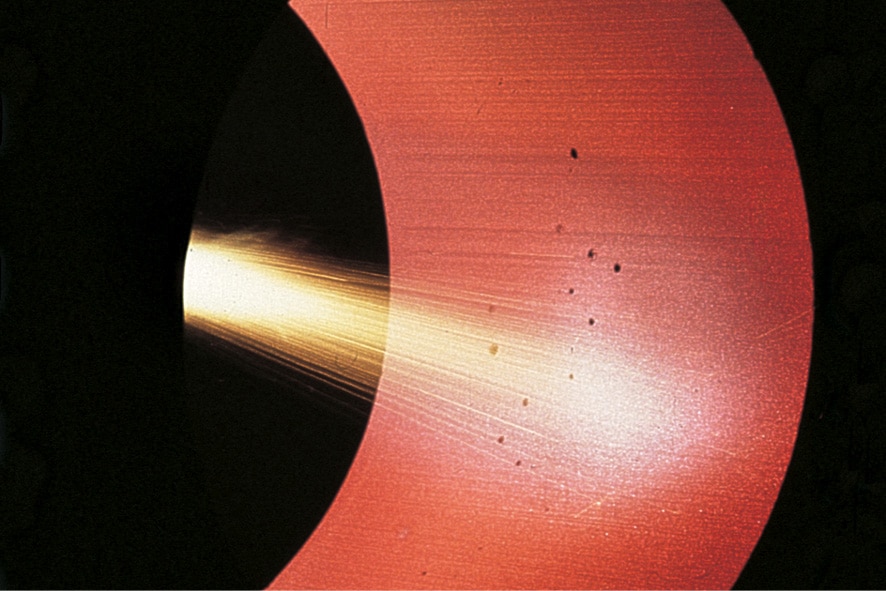

- Combustion of acetylene with oxygen

- Flame temperature: 2,000-3,000 °C

- Particle speed: 50-100 m/s