Skilled metalworking

The skilled technicians of Bekkers repair and overhaul the most diverse range of machine components – from a minute axle to an enormous roller drum.

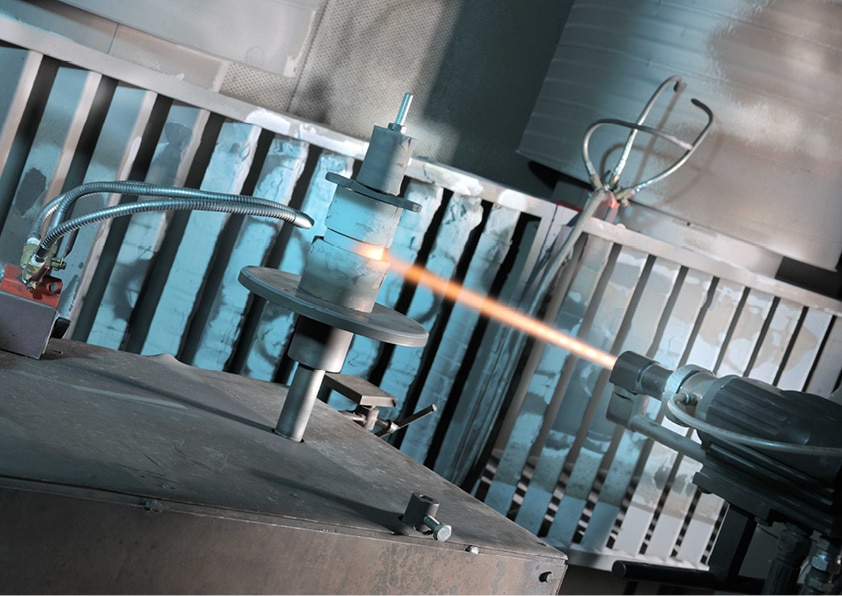

Thermal spraying

Thermal spraying involves the application of a metal, ceramic or synthetic layer on a surface to give it specific properties – e.g., wear resistance.

State of the art

Bekkers is renowned for its long experience in craftsmanship – the perfect basis for the ultramodern techniques that the company now applies.

Introduction

Thermal spraying is a technique whereby a material, be it metal or ceramic or synthetic, in wire or powder form is heated by means of a thermal spray gun and sprayed on a surface. This results in a covering layer with improved properties for the function of the component.

Thermal spraying is, with only one exception, a cold process, meaning that despite the heat source of the spray gun with which the metal is melted and sprayed, the processed component will only experience a slight temperature increase from the heat transfer of the deposited droplets. No deformation, changing structure or mixing can take place at the customary spraying temperature of 50° to 200° C.

A cold sprayed layer has a lamellar structure, somewhat comparable to a cast iron structure. In case of some sprayed metal layers, micropores and oxide inclusions can lead to a low friction coefficient and extreme hardness. Also, microporous spray layers offer a high absorption of lubricants, thereby preventing wear caused by metal on metal contact.

Properties thermally sprayed layers

- Thin (20 µm) to thick layers (7 mm)

- Surface roughness, sprayed 1-50µm Ra

- Treated: to approx. 0.01µm Ra

- Internal and external surfaces

- Nearly independent of workpiece size