Skip to main content

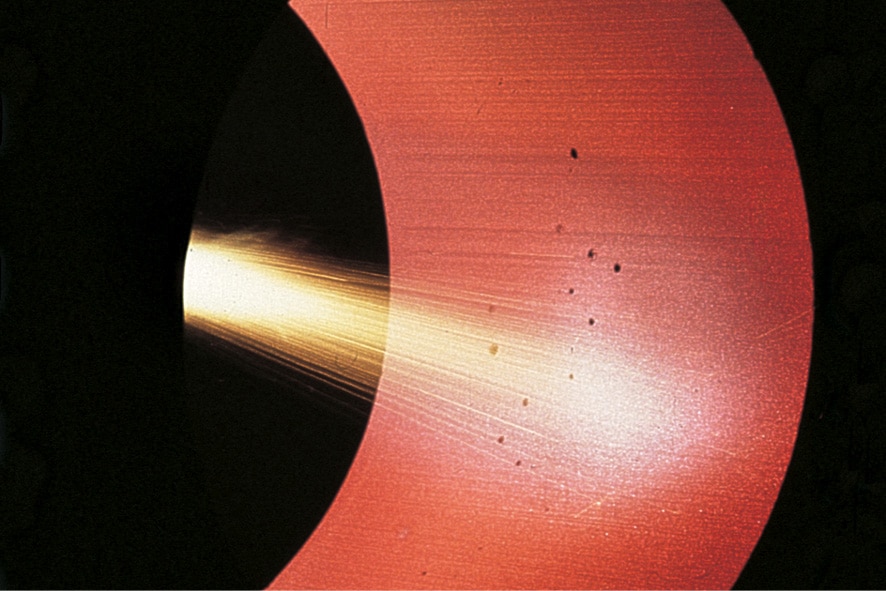

Autogenous powder spraying

Typical Spray Coats

Self-flowing alloys (fusing)

Ni/Fe/Mo base materials

Ceramics/cermets

Wear-resistant layers (Ni-graphite)

Plastics (e.g. Rilsan, polyamide)

Material form: powder

Combustion of acetylene with oxygen

Flame temperature: 2,000-3,000 °C

Particle speed: 50-100 m/s

After-treatment by fusing (“fusing”)

Heat part to 1,000°C to 1,200°C

Provides a homogeneous coating structure (“no” porosity)

Adhesion principle is based on diffusion

Suitable for all types of heavy loads (impact resistant)

Plasma spraying

Applications: wear resistance, corrosion resistance, thermal insulation, electrical insulation.

HVOF

Typical spray coatings: Ni-/Co alloys / stainless, carbides / cermets

Electrical wire spraying

Ni-/Fe base alloys/stainless steel, molybdenum/aluminium, copper and copper alloys, zinc, tin, etc

Autogenous wire spraying

Ni/Fe base alloys, molybdenum/aluminium, copper and copper alloys, zinc, tin, etc.

Autogenous powder spraying

Self-flowing alloys, Ni/Fe/Mo base materials, ceramics/cermets and ctr

Would you like to get in touch with us or do you have any questions and/or comments? We like to help you!

We use cookies to ensure that we give you the best experience on our website. If you continue to use this site we will assume that you are happy with it. Ok Privacy policy